In the realm of automotive engineering, the transmission system plays a pivotal role in transferring power from the engine to the wheels. Among the myriad of transmission options available, the 4T65E transmission stands out as a notable choice, renowned for its reliability and performance. This article delves into the intricacies of the 4T65E transmission, exploring its design, functionality, common issues, and maintenance requirements.

Understanding the 4T65E Transmission

Origins and Evolution

The 4T65E transmission, developed by General Motors (GM), made its debut in the late 1990s. It was designed as an upgrade to its predecessor, the 4T60E transmission, with enhancements aimed at improving durability and efficiency. Over the years, the 4T65E underwent several iterations and refinements, incorporating technological advancements to meet the evolving demands of the automotive industry.

Design and Components

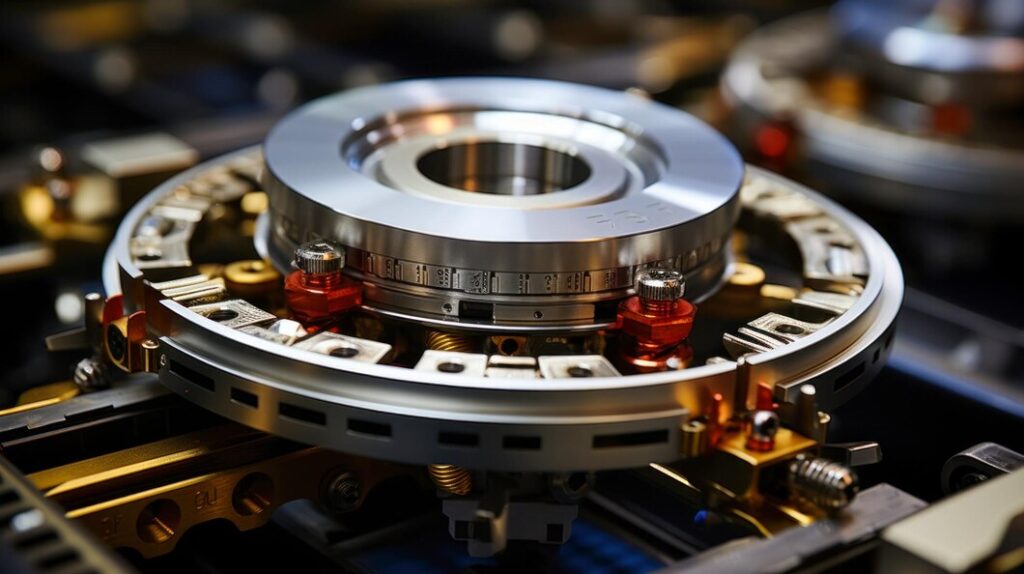

At its core, the 4T65E is a four-speed automatic transmission equipped with electronic controls (hence the ‘E’ in its name). It features a robust construction, comprising various components such as gears, clutches, bands, valves, and solenoids, all meticulously engineered to ensure seamless operation and longevity.

Functionality of the 4T65E Transmission

Power Transfer Mechanism

The primary function of the 4T65E transmission is to regulate the distribution of power generated by the engine to the wheels, thereby enabling smooth acceleration and efficient operation of the vehicle. This process involves the precise engagement and disengagement of gears and clutches, facilitated by the transmission control module (TCM) based on input from various sensors.

Gear Ratios and Performance

The 4T65E transmission offers a range of gear ratios tailored to optimize performance across different driving conditions. These ratios determine the torque multiplication and speed output, allowing the vehicle to achieve the desired balance between acceleration, fuel efficiency, and engine RPM.

Common Issues and Troubleshooting

Gear Slipping

One of the most prevalent issues encountered with the 4T65E transmission is gear slipping, characterized by abrupt changes in gear engagement or unexpected shifts while driving. This problem can stem from various factors, including worn clutch plates, valve body malfunctions, or low transmission fluid levels. Diagnosing the root cause typically involves conducting a thorough inspection and, if necessary, performing repairs or replacements as recommended by certified technicians.

Fluid Leaks

Fluid leaks are another common issue that plagues the 4T65E transmission. These leaks can occur due to deteriorated seals, damaged gaskets, or loose fittings, leading to a gradual loss of transmission fluid. Left unaddressed, fluid leaks can compromise the transmission’s lubrication and cooling capabilities, ultimately resulting in premature wear and potential damage to internal components. Prompt identification and repair of leaks are essential to prevent further complications and ensure the transmission’s longevity.

Solenoid Failures

Solenoids play a critical role in regulating fluid flow and pressure within the 4T65E transmission. When these solenoids malfunction or fail, it can disrupt the transmission’s operation, causing symptoms such as erratic shifting, harsh engagement, or failure to shift gears altogether. Solenoid issues may arise due to electrical faults, mechanical failures, or contamination from debris or sediment in the transmission fluid. Addressing solenoid-related issues often involves testing, cleaning, or replacing the affected components as necessary.

Maintenance and Care Guidelines

Regular Fluid Checks and Changes

Maintaining the proper level and condition of transmission fluid is paramount to the longevity and performance of the 4T65E transmission. Periodic fluid checks and changes, as recommended by the manufacturer, help ensure optimal lubrication, cooling, and friction control within the transmission system.

Scheduled Inspections and Servicing

Routine inspections and servicing by qualified professionals are essential to detect any potential issues with the 4T65E transmission early on and prevent them from escalating into major problems. This includes checking for leaks, assessing the condition of internal components, and conducting diagnostic tests to identify any abnormal behavior or fault codes.

Driving Habits and Conditions

Adopting responsible driving habits and avoiding excessive loads or harsh driving conditions can significantly reduce the strain on the 4T65E transmission and prolong its lifespan. Gentle acceleration, smooth shifts, and avoiding towing or hauling beyond the recommended capacity can help mitigate wear and tear on the transmission components.

Conclusion

The 4T65E transmission represents a culmination of engineering ingenuity and technological innovation, offering a reliable and efficient solution for power transfer in automotive applications. By understanding its design, functionality, common issues, and maintenance requirements, vehicle owners can ensure the optimal performance and longevity of their 4T65E-equipped vehicles, keeping them on the road for years to come.